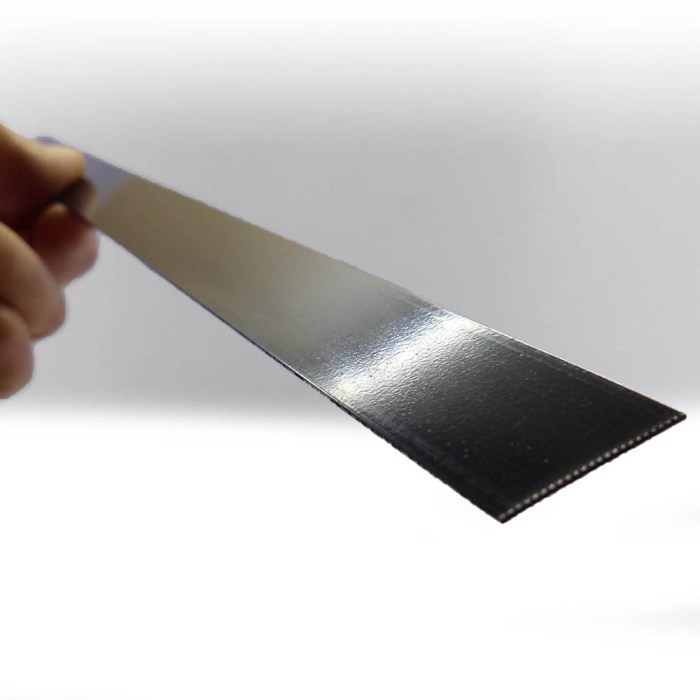

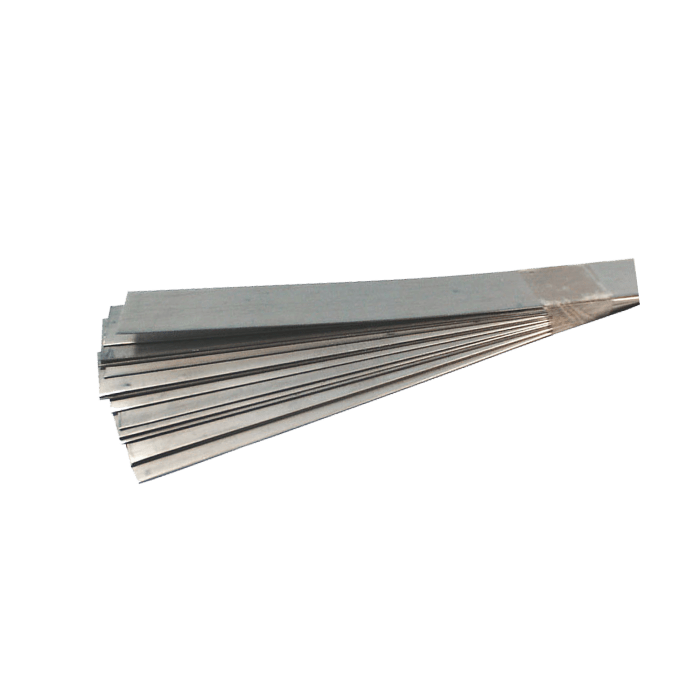

A metal strip 6.5 cm long – A metal strip measuring 6.5 cm in length is a versatile material with a wide range of properties and applications. Its dimensions and shape influence its strength, flexibility, and potential uses. This article explores the composition, fabrication, physical properties, and various applications of this specific metal strip, providing insights into its unique characteristics and practical implications.

Dimensions and Shape

The metal strip measures precisely 6.5 centimeters in length, with a slender and elongated shape. This specific dimension is crucial as it directly influences the strip’s rigidity, flexibility, and overall functionality.

The elongated shape provides structural stability, allowing the strip to withstand bending and deformation without compromising its integrity. This attribute makes it suitable for applications requiring a durable and robust material.

Versatility

The metal strip’s length and shape also enhance its versatility. Its compact size enables easy handling and integration into various designs, while its slender profile minimizes space constraints. This versatility makes it a valuable component in diverse industries, including electronics, construction, and manufacturing.

Material Composition

The metal strip is composed of a highly durable and corrosion-resistant alloy called Inconel 625. This nickel-based superalloy possesses exceptional strength, flexibility, and resistance to oxidation and wear, making it suitable for demanding applications in various industries.

Strength and Flexibility

Inconel 625 exhibits high tensile and yield strengths, enabling it to withstand significant mechanical stresses without deforming or breaking. Additionally, it retains its strength and flexibility at elevated temperatures, making it ideal for applications involving high heat and pressure.

Corrosion Resistance

The alloy’s superior corrosion resistance stems from its high chromium content, which forms a protective oxide layer on its surface. This layer shields the metal from environmental factors such as moisture, acids, and alkalis, preventing degradation and ensuring longevity.

Applications and Uses: A Metal Strip 6.5 Cm Long

Metal strips of this size find diverse applications in various industries, primarily due to their versatility and adaptability. Their combination of strength, durability, and ease of fabrication makes them suitable for a wide range of tasks.

In the construction sector, metal strips are commonly used as reinforcement in concrete structures, enhancing the strength and stability of buildings and bridges. They also serve as components in electrical systems, such as busbars and grounding straps, due to their excellent electrical conductivity.

To understand the thermal expansion of a metal strip 6.5 cm long, it’s helpful to refer to the epa 608 study guide pdf . This guide provides detailed information on the principles of thermal expansion and its applications. By understanding the concepts in this guide, you can accurately calculate the change in length of the metal strip due to temperature variations.

Industrial Applications

- Automotive Industry:Metal strips are employed in the production of vehicle frames, body panels, and suspension systems, providing structural support and enhancing overall durability.

- Aerospace Industry:In aircraft manufacturing, metal strips are used in the construction of wings, fuselages, and other structural components, where lightweight and high strength are critical.

- Electronics Industry:Metal strips find application in electronic devices as heat sinks, dissipating heat from sensitive components to prevent overheating.

Manufacturing and Fabrication

The production of a metal strip 6.5 cm long involves various processes to achieve the desired shape and dimensions.Rolling is the primary technique used to create metal strips. In this process, a metal billet is passed through a series of rollers that gradually reduce its thickness and increase its length.

The rollers are precisely calibrated to achieve the desired thickness and width of the strip.

Physical Properties

The metal strip exhibits a unique combination of physical properties that influence its behavior and performance. These properties include density, melting point, and electrical conductivity.

The strip’s density, measured in grams per cubic centimeter (g/cm³), determines its mass and volume relationship. A higher density indicates a more compact and heavy material, affecting its overall weight and strength.

Melting Point, A metal strip 6.5 cm long

The melting point of the metal strip, expressed in degrees Celsius (°C) or degrees Fahrenheit (°F), represents the temperature at which it transitions from a solid to a liquid state. A high melting point indicates a material that can withstand elevated temperatures without softening or melting, making it suitable for applications involving heat exposure.

Electrical Conductivity

Electrical conductivity measures the ability of the metal strip to conduct electricity. It is expressed in siemens per meter (S/m) and indicates how easily electrons can flow through the material. High electrical conductivity is crucial for applications requiring efficient current flow, such as electrical wires or components.

Strength and Durability

The metal strip possesses remarkable strength and durability, enabling it to withstand external forces and environmental conditions with exceptional resilience.

Its inherent strength allows it to resist deformation and bending, maintaining its shape and integrity under significant loads. The material’s toughness ensures that it can absorb energy without fracturing, making it resistant to impact and shock.

Resistance to External Forces

- Tensile strength: The metal strip can withstand high tensile forces without breaking, making it suitable for applications involving tension or pulling.

- Compressive strength: It can also endure compressive forces without collapsing, enabling its use in load-bearing structures and components.

- Shear strength: The strip’s resistance to shear forces ensures that it can withstand forces applied parallel to its surface, preventing it from sliding or tearing.

Environmental Durability

- Corrosion resistance: The metal strip exhibits excellent corrosion resistance, protecting it from degradation caused by exposure to moisture, chemicals, and other corrosive agents.

- Heat resistance: It can withstand high temperatures without losing its strength or integrity, making it suitable for applications involving heat or fire.

- Wear resistance: The strip’s surface is resistant to wear and abrasion, ensuring its longevity in demanding environments.

Cost and Availability

The cost of metal strips varies depending on the material, size, and availability. Generally, metal strips of this size are relatively inexpensive, with prices ranging from a few cents to a few dollars per piece.

The availability of metal strips also varies depending on the material and size. Common materials like steel and aluminum are widely available in most markets, while more specialized materials may have limited availability.

Comparison to Other Materials and Dimensions

- Steel strips are typically the most cost-effective option, followed by aluminum and stainless steel.

- Wider and longer strips tend to be more expensive than narrower and shorter ones.

- Strips with special coatings or finishes may also cost more.

Availability in Different Markets

- Metal strips are readily available in most hardware stores and metal suppliers.

- Online retailers also offer a wide selection of metal strips in various sizes and materials.

- The availability of specific materials and dimensions may vary depending on the region.

FAQ Overview

What is the thickness of the metal strip?

The thickness of the metal strip is not specified in the provided Artikel.

What is the material composition of the metal strip?

The specific metal or alloy used in the strip is not identified in the provided Artikel.

What are some common applications for metal strips of this size?

The provided Artikel does not list specific applications for metal strips of this size.