The kern of a kernmantle rope is its core component, providing strength, durability, and safety. Understanding the kern’s structure and function is crucial for selecting and maintaining ropes in various applications.

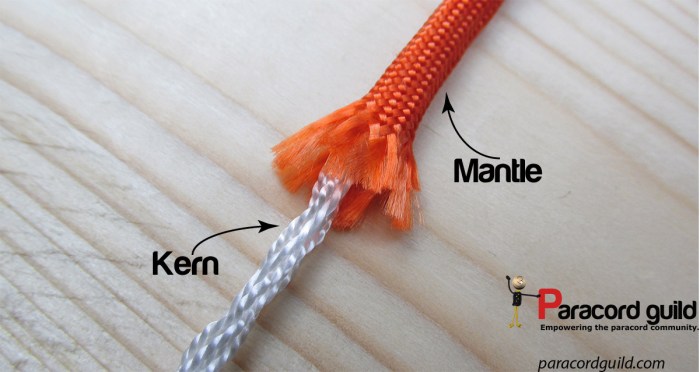

The kern, typically made of synthetic fibers like nylon or polyester, is surrounded by a woven mantle that protects it from abrasion and damage. Its construction, including diameter, strand count, and lay direction, significantly influences the rope’s overall performance and safety.

The Kern of a Kernmantle Rope: The Kern Of A Kernmantle Rope Is Its

The kern is the central core of a kernmantle rope, responsible for providing strength and load-bearing capacity. It consists of twisted or braided strands made from high-tenacity materials such as nylon, polyester, or Dyneema. The choice of material impacts the rope’s strength, flexibility, and durability.

The kern is distinct from the mantle, which surrounds and protects the kern from abrasion and environmental factors.

The Role of the Kern in Rope Strength and Durability

The kern, the inner core of a kernmantle rope, plays a pivotal role in determining the overall strength and durability of the rope. It is composed of tightly twisted fibers that provide the rope with its tensile strength, the ability to resist breaking under tension.

Relationship between Kern Diameter and Rope Strength

The diameter of the kern is directly proportional to the rope’s strength. A larger kern diameter indicates a greater number of fibers, resulting in a higher tensile strength. For example, a 10mm rope with a 5mm kern will typically have a higher breaking strength than a 10mm rope with a 4mm kern.

Kern Construction and Durability

The construction of the kern also influences the rope’s durability. A kern made of high-quality fibers, such as nylon or Dyneema, will be more resistant to wear and tear than a kern made of lower-quality fibers. Additionally, the twist of the fibers affects the kern’s durability.

A tightly twisted kern is more resistant to abrasion and damage than a loosely twisted kern.

The Impact of Kern Design on Rope Performance

The kern, a central load-bearing component within a kernmantle rope, plays a crucial role in determining the overall performance, flexibility, and durability of the rope. Different kern designs offer distinct advantages and disadvantages, catering to specific applications and user requirements.

Kern Strand Count, The kern of a kernmantle rope is its

The number of strands within the kern influences rope flexibility and handling characteristics. A higher strand count generally results in a more flexible rope, making it easier to handle and maneuver. However, a higher strand count also increases rope weight and diameter, which may not be desirable for certain applications.

Kern Lay Direction

The lay direction of the kern strands affects rope handling and performance. A left-hand lay kern tends to be more resistant to kinking and twisting, while a right-hand lay kern provides better abrasion resistance. The choice of lay direction depends on the intended use of the rope.

Fiber Orientation

The orientation of fibers within the kern strands can influence rope strength and durability. Fibers oriented parallel to the rope axis provide higher tensile strength, while fibers oriented perpendicularly enhance transverse stiffness and reduce rope elongation.

Examples of Optimized Kern Designs

- Climbing ropes:High strand count, left-hand lay kern for flexibility and knot-holding ability.

- Caving ropes:Low strand count, right-hand lay kern for abrasion resistance and handling in wet environments.

- Industrial ropes:High-strength fibers, parallel fiber orientation for maximum tensile strength.

The Kern as a Safety Critical Component

The kern is the heart of a kernmantle rope, providing the strength and durability that climbers and other rope users rely on for their safety. It is the load-bearing component of the rope, responsible for absorbing and distributing the forces generated during climbing and other activities.

The failure of the kern can have catastrophic consequences, potentially leading to serious injury or even death. Therefore, it is crucial to ensure that the kern is in good condition and regularly inspected and maintained.

Assessing Kern Condition

Assessing the condition of the kern is essential for ensuring the safety of a rope. There are several key indicators that can help determine whether a rope should be retired:

- Visual inspection:Look for any signs of damage or wear, such as cuts, nicks, or abrasions. These can weaken the kern and compromise its strength.

- Feel test:Run your hands along the rope to check for any lumps, bumps, or soft spots. These can indicate damage to the kern or other internal components.

- Knot test:Tie a few knots in the rope and then untie them. If the knots are difficult to untie or leave any permanent deformation in the rope, it may be a sign of kern damage.

- Dynamic testing:This involves subjecting the rope to a series of controlled falls to assess its dynamic strength and energy absorption capacity. This type of testing is typically performed by rope manufacturers or certified testing facilities.

Determining When to Retire a Rope

The decision of when to retire a rope is based on a combination of factors, including the age of the rope, the frequency and severity of use, and the results of regular inspections.

As a general guideline, most manufacturers recommend retiring a kernmantle rope after 5-10 years of use, depending on the specific type of rope and the conditions it has been exposed to.

However, it is important to note that some ropes may need to be retired sooner if they have been subjected to excessive wear or damage. It is always better to err on the side of caution and retire a rope if there is any doubt about its safety.

Common Queries

What is the difference between the kern and mantle of a kernmantle rope?

The kern is the inner core that provides strength, while the mantle is the outer layer that protects the kern from abrasion and damage.

How does the kern diameter affect rope strength?

A larger kern diameter generally increases rope strength, but it also makes the rope stiffer and less flexible.

What is the importance of regular rope inspection?

Regular inspection helps identify any damage to the kern or mantle, ensuring the rope remains safe for use.